ELGI’s EN Series screw compressors are known for their reliability, low maintenance requirements, and compact design, making them ideal for industrial applications where size, efficiency, and cost are important.

ELGI’s EG series compressors represent a significant leap in design and performance, with each component crafted for reliability and ease of maintenance. These compressors are built to deliver enhanced efficiency and long-lasting reliability for industrial applications.

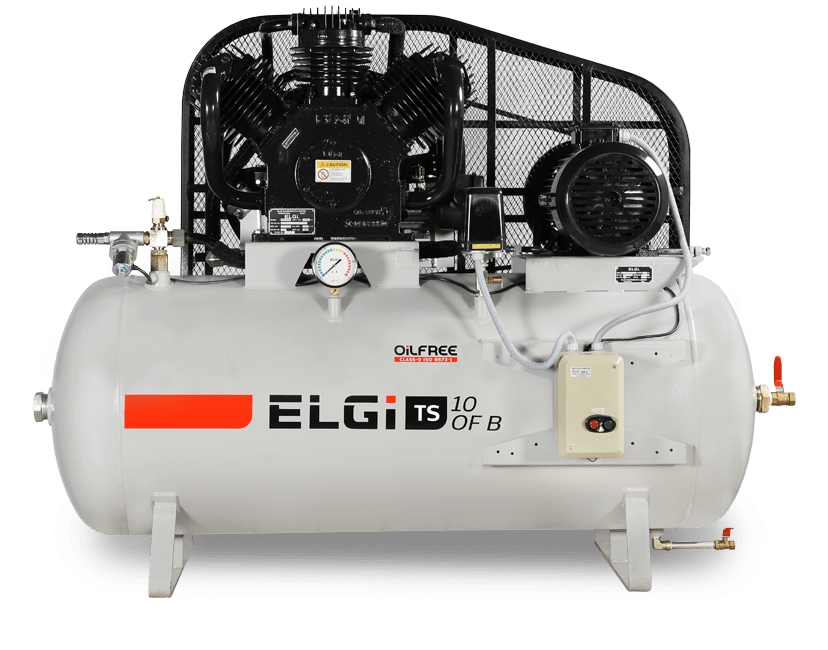

ELGI is one of the few compressor manufacturers to design and produce its own oil-free compressor block in-house. Their oil-free range offers zero-class air with leading energy efficiency, reliability, and low operating costs.

The AB series oil-free screw compressors feature an optimized layout for easy maintenance with reduced downtime. They ensure minimal energy loss, low air discharge temperatures, and are highly reliable and compact. These compressors are designed with superior safety standards, making them an excellent choice for energy-efficient, dependable operations.

Oil-lubricated air compressors are essential in various industries for driving tools and machines by compressing air into a storage tank. This guide delves deeper into their internal workings, including the compression process, lubrication system, and the benefits of oil for improved efficiency.

Oil-lubricated piston compressors work by drawing in air and compressing it. Smooth operation is key, and this is achieved with an effective lubrication system. The compression process involves:

The lubrication system is crucial for smooth operation and long lifespan. Oil reduces friction between moving parts, dissipates heat, and prevents wear. Key components of the lubrication system include:

Oil is crucial for preventing wear and enhancing performance. Some benefits include:

Discover how oil-lubricated air compressors can help your business! Contact us today for more information.